全国热线

0537-3657638

产品简介:

智能远控远控旋连胶链带称重给料机一、结构原理特征及效果I.Structuralprinciplefeaturesandeffects1、在煤仓口处设置平除仓压铰接点,铰接点将煤仓仓压分成...产品详情

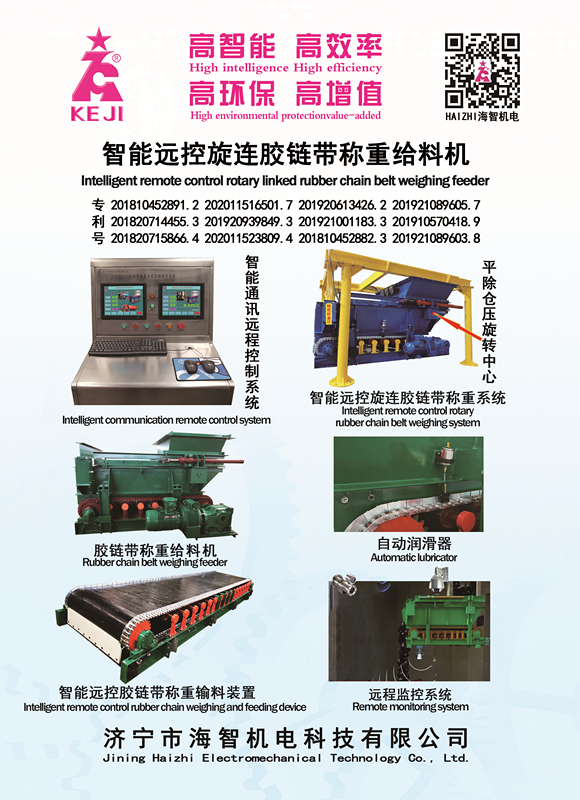

智能远控远控旋连胶链带称重给料机

一、结构原理特征及效果

I.Structural principle features and effects

1、在煤仓口处设置平除仓压铰接点,铰接点将煤仓仓压分成仓压前影响区和仓压后影响区,经计算及精密加工确保仓压前影响区和仓压后影响区相对于平除仓压铰接点两侧的作用力矩大小相等方向相反;

1. At the coal bunker opening, a hinge joint point for flat release of bunker pressure is set, which divides the coal bunker pressure into the affected area before and after the bunker pressure. After calculation and precision machining, it shall be ensured that the applied moment of the affected area before and after the bunker pressure is equal to but opposite to the action moment on both sides of hinge joint point for flat release of bunker pressure.

2、称重传感器铰接吊挂在给料机卸料端,给料机后部通过铰轴挂在煤仓口,给料机可绕铰轴旋转,称重传感器检测铰接悬挂的给料机卸料端部物料瞬时重量,同时速度传感器检测输送带的运行速度,通过称重仪表将重量信号和速度信号积分运算,获得物料重量;

2. The weighing sensor is hinged and hung at the discharge end of the feeder, and the rear part of the feeder is hung at the coal bunker opening through the hinged shaft. The feeder can rotate around the hinged shaft. The weighing sensor detects the instantaneous weight of the material at the discharge end of the feeder hinged and hung, and the speed sensor detects the running speed of the conveyor belt. The weight signal and the speed signal are integrated by the weighing instrument to obtain the material weight.

3、用天平的原理,将称重传感器铰接悬挂在给料机卸料端部,将导料斗输送底盘作为秤盘,消除了各种干扰称重精度因素,例如消除了①输送带张紧力变化、②仓压大小变化、③物料密度变化、④物料冲击振动变化、⑤物料输送摩擦系数变化、⑥导料槽与输送带间挤料、⑦机械输送部分阻力变化、⑧环境温度变化、⑨闸门装车时存在关闭延时造成的装车重量误差等,使称重长期精准稳定;

3. Based on the principle of the balance, the weighing sensor is hinged and hung at the discharge end of the feeder, and the conveying chassis of the drop guide hopper is used as the scale to eliminate all kinds of interference factors for weighing, such as ① the change of the tension of the conveyor belt, ② the change of the bunker pressure, ③the change of the material density, ④the change of the material impact shock, ⑤ the change of the friction coefficient of the material conveying, ⑥the material extrusion between the guide chute and the conveyor belt, ⑦resistance change of mechanical conveying part, ⑧environmental temperature change, etc., so as to make weighing accurate and stable for a long time, ⑨loading weight error caused by the closing delay when the gate is loaded;

4、胶链带用高附着力柔性胶带与特钢加长横穿条一体成型,抗严寒酷夏,结冰不打滑挠度好,不跑偏、耐磨损,冷不缩热不胀不变形,胶链带链节与链轮稳定啮合,抗拉强度大,长期无人值守大量配煤,3-5年免维护,给料快速、精准、稳定,提高效率60%以上;

4. The flexible tape with high adhesion for plastic hinge belt is integrally formed with the special-steel extended cross bar. It is resistant to severe cold and hot summer, does not slip when it is frozen, does not drift, is resistant to wear, and does not shrink when it is cold nor expand when it is hot. The chain link of rubber chain belt is stably meshed with the sprocket, the tensile strength is large, the long-term unmanned mass coal blending is carried out, the maintenance is free for 3-5 years, the blending is fast, accurate and stable, and the efficiency is improved by more than 60%;

5、长期称重准确度:99.99%-99.7%,配煤成本低、精度高、损耗低;

5.Long-term weighing accuracy: 99.99% to 99.7%, low coal blending cost, high precision and low loss;

6、通过铰接悬挂输送底盘(秤盘)称重,整机长度短,安装空间小,精度高;

6. The weighing is carried out through the conveying chassis (scale) hinged and hung, and the whole machine is short, small in installation space and high in precision.

7、变频器采用BPB-22/660型矿用隔爆型变频调速器,散热好,操作不需要开门;控制灵活,可实现就地和远程控制;精度高、噪音低、转矩大、性能可靠;

7. BPB-22/660 mine flameproof frequency conversion governor is adopted. It has good heat dissipation and does not need to open the door for operation; it is flexible in control, and can realize local and remote control; it has high precision, low noise, large torque and reliable performance;

8、护带柔性清扫器,设于卸料口处,阻止物料随带回程,配重使柔性除料刷始终贴紧胶链带,将物料刷至落料口;

8. The flexible sweeper for protecting the belt is arranged at the discharge opening to prevent the material from returning with the belt. The counterweight makes the flexible material removing brush always stick to the rubber chain belt and brush the material to the discharge opening;

9、刮料器齿轮由胶链带链条带动,给料清料同步,无回程料堆积,集料斗设置在机底架内,整机无漏料无漏水,清回程料不增加整机高度,结构精巧、简单、牢固;

9. The scraper gear is driven by the rubber chain belt chain, feeding and clearing are synchronous without accumulation of return materials. The collecting hopper is arranged in the chassis of the machine, and the whole machine has no material leakage or water leakage, and the height of the whole machine is not increased by clearing the return materials. The structure is exquisite, simple and firm.

10、在胶链带链条上部设有自动感应润滑油壶,其在未给料时,自动关闭出油口,滚子链运行带动润滑油壶出油,润滑油通过刷油器对滚子链、齿轮等全方位刷油润滑;

10. The upper part of the rubber chain belt is provided with an automatic induction lubricating oil pot, which automatically closes the oil outlet when no material is fed, and the roller chain runs to drive the lubricating oil pot to give oil. The lubricating oil brushes the roller chain, gears and the like in all directions for lubrication;

11、其设有感应链条运转长度计数器,当运转数值达到自动加油值时,PLC编程系统控制电动润滑泵,自动向润滑油壶注油,实现无人值守长期安全给滚子链、齿轮等自动感应润滑(选配);

11. It is equipped with an induction chain running length counter. When the running value reaches the automatic oiling value, the PLC programming system controls the electric lubricating pump to automatically oil the lubricating oil pot, thus realizing unattended long-term safe automatic induction lubrication of roller chains and gears (optional).

12、视频摄像头对旋连平除仓压胶链带称重给料机全方位录像,远程监控装置显示给料机实时运行状态并储存运行录像(选配);

12. The video camera records the rotary leveling and unloading pressure rubber chain belt weighing feeder in all directions, and the remote monitoring device displays the real-time running state of the feeder with the video saved (optional);

13、根据给料需要,远程开启、调整、停止旋连平除仓压胶链带称重给料机运行,实现现场无人值守远程视频录像控制(选配);

13. According to the feeding requirements, it remotely starts, adjusts and stops the rotary leveling and unloading pressure rubber chain bel weighing feeder to realize the unattended remote video control on site (optional);

14、给料机传动原理改进,与同体积其他给煤机相比给煤量提升20%以上,有效提高了胶链带给料面线速度,实现了有限尺寸给煤量最大化,整机结构稳定牢固,运行长期安全无人值守。

14. The feeder transmission principle is improved, and compared with other coal feeders with the same volume, the coal feeding amount is increased by more than 20%, which effectively improves the linear speed of the coal feeding side of the rubber chain belt, and maximizes the coal feeding amount with limited size. The whole machine structure is stable and firm, and the unattended operation is safe for a long time.

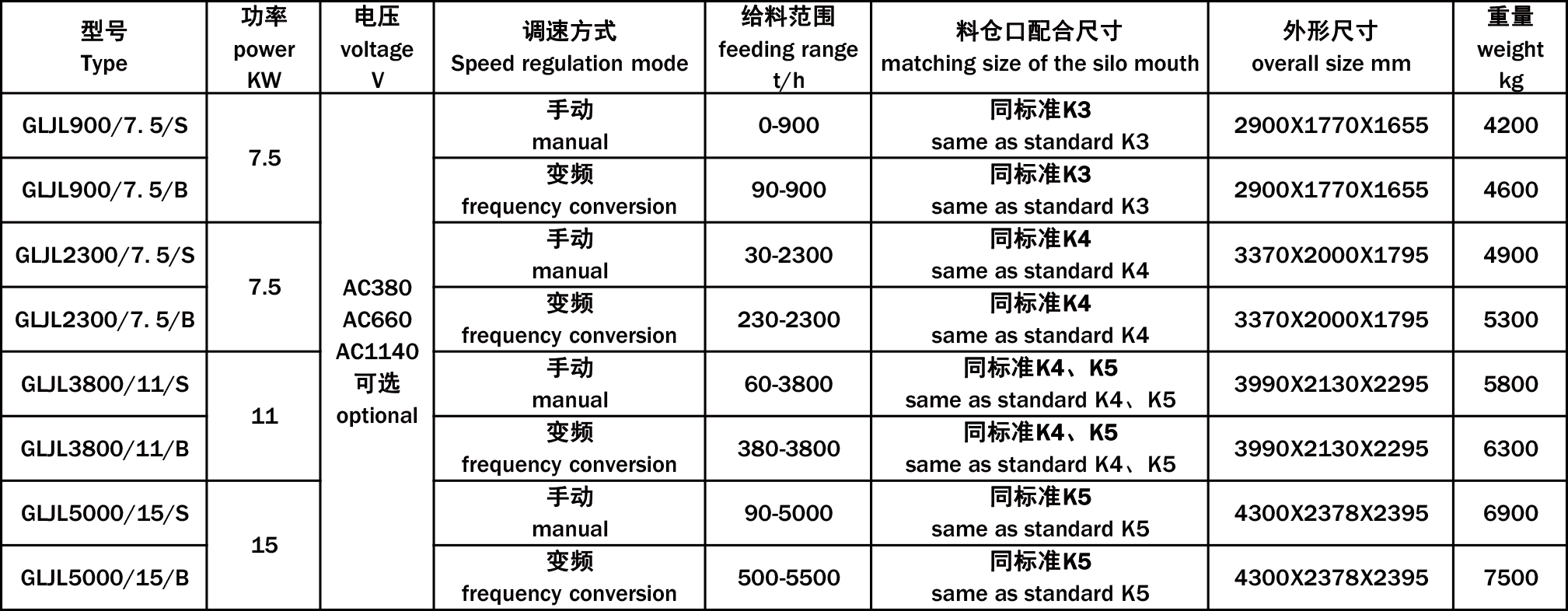

二、智能远控旋连胶链带称重给料机主要技术参数

II. Main technical parameters of intelligent remote control rotary rubber chain weighing feeder

三、海智机电可根据用户需求及现场工况,针对性设计高性能、高效率、高环保、高安全的胶链带称重给料机,确保该机3-5年免维护,为用户大量省维护、增效益,让用户用得省心、放心、开心!!!

IV. The Company is able to design high-performance, high-efficiency, high-environmental protection, high-safety plastic hinge feeder according to the user’s various needs and on-site working conditionsto ensure that the machine is free of maintenance for 3-5 years, so as to save maintenance costs and increase benefits for the users and make the users feel assured, relieved and happy with the products!!!

全国咨询服务热线

0537-3657638